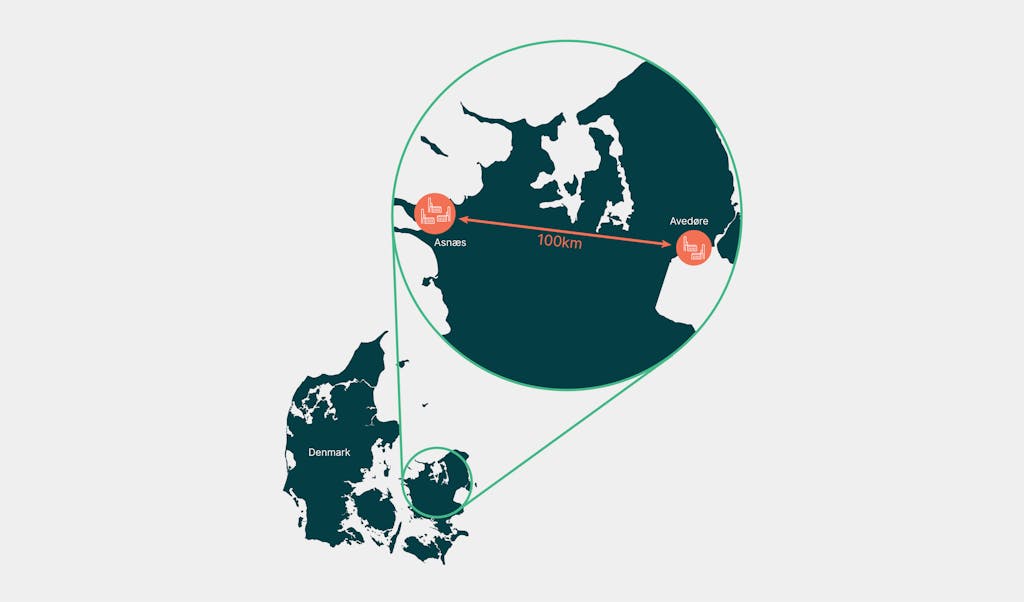

Ørsted Kalundborg CCS

Aker Carbon Capture has been awarded a large-scale carbon capture project by Ørsted, a global leader in renewable energy, for its Ørsted Kalundborg Hub in Denmark. As the carbon capture provider, Aker Carbon Capture will deliver five Just Catch units, additional equipment such as liquefaction systems, and temporary CO2 storage and on-/offloading facilities with an expected total contract value above EUR 200 million. The carbon capture facilities will be delivered to Ørsted’s wood chip-fired Asnæs Power Station and the Avedøre Power Station’s straw-fired boiler.

Year

2023CO₂ capture capacity

500.000 TPA

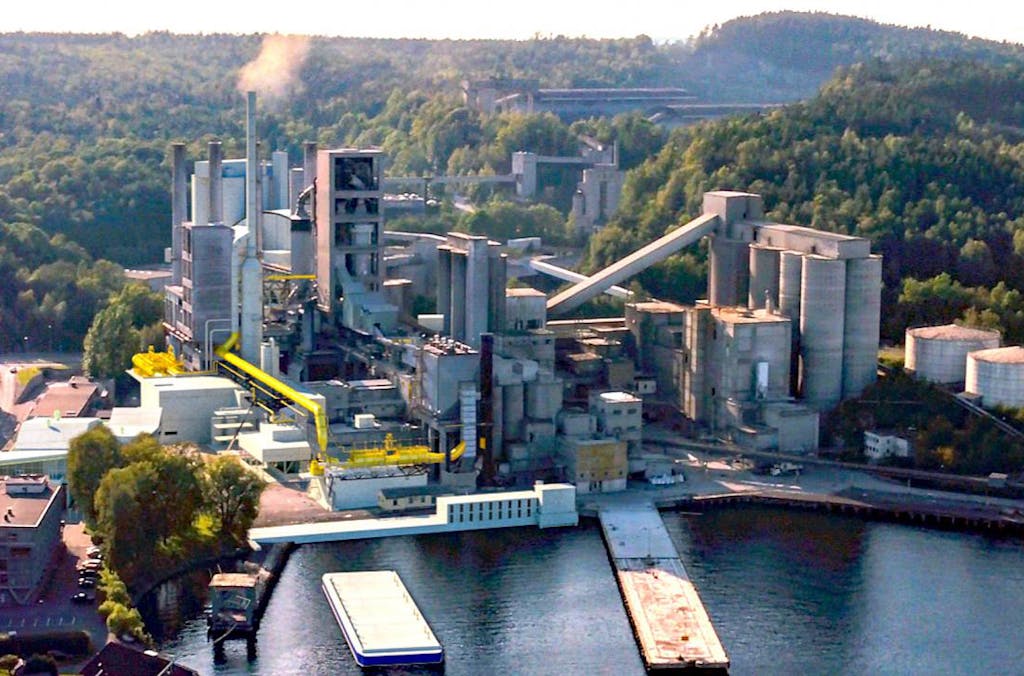

Brevik Cement Plant

Aker Carbon Capture has worked together with Heidelberg Norcem and partners in developing a full-scale CO₂ capture, conditioning, compression, heat integration, intermediate storage and loading facility for the Brevik cement plant. The capacity of the carbon capture facility corresponds to approximately half of the annual CO₂ emissions from the Brevik plant. CO₂ is to be captured from the flue gases of the cement kiln using waste heat recovered from the cement plant and the CO₂ compression plant through a proprietary heat integration technology.

Year

2020 – 2024 (ongoing)CO₂ capture capacity

400.000 TPA

Photo: HeidelbergCement

Twence CCU

Aker Carbon Capture was awarded a delivery contract for a CO₂ capture and liquefaction facility for waste-to-energy plant in the Netherlands. The produced CO₂ will be of Food Grade quality in order to transport the CO₂ to nearby greenhouses where it is to be used to increase the yield of flowers and vegetables. Aker Carbon Capture will deliver its Just Catch™ modular capture plant which is a standardized, compact carbon capture facility. The plant comprises of three process containers and one E&I container for local control. Containers and associated external piping and structures will be prefabricated at a yard, and transported by truck to the actual site. The columns, fan and steam reboiler will be delivered directly to site for easy hook-up with the containers. The plant will be fully automated and is based on the Advanced Carbon Capture (ACC™) Process with the proprietary, best in class HSE solvent.

The Just Catch™ is characterized by short delivery time, low cost and low required footprint. The plant is currently scheduled to be delivered late 2023.

Year

2023 (ongoing)CO₂ capture capacity

100.000 TPACustomer

Twence

Forus Energigjenvinning

Forus Energigjenvinning is the largest emitter in Rogaland region on the west coast of Norway. Aker Carbon Capture is working with Forus Energigjenvinning and Lyse in a partnership through feasibility and further development of a Just Catch 100 carbon capture plant. The collaboration has now been extended to develop a plan for the entire region looking at additional sources of CO₂ as well as integrating to other environmental projects.

Year

2020 – 2024 (ongoing)CO₂ capture capacity

100.000 TPA

Preem refinery

Preem and Aker Carbon Capture has been working with SINTEF, Chalmers and Equinor at the Lysekil Refinery in Sweden piloting capture from a Steam Methane Refiner (SMR) hydrogen production unit. Aker Carbon Capture is performing a nearly one-year test program on the flue gas as well as developing a feasibility study for a 400 000 capture unit. The project is one of Preem transition projects for their business in Scandinavia.

Year

2020CO₂ capture capacity

~600.000 TPA

Amager Bakke (Ski Slope)

ARC worked with Aker Carbon Capture to conduct a pre-feasibility study to assess large scale carbon capture with heat integration. Utilizing Aker Carbon Capture’s energy optimization experts, the study included evaluation of the possibility of “zero parasitic load”, meaning using advanced heat integration at their planned site and reusing the waste heat further in the district heating. ARC has applied for EU Innovation Fund with their project which is one of the enablers of the City of Copenhagen 2025 target – net zero.

Year

2020CO₂ capture capacity

~500.000 TPA

Credit: Hufton&Crow, ARC

Heat integration technology

Aker Carbon Capture and MAN Energy Solutions have signed a technology-cooperation agreement to develop energy-efficient compression solutions for carbon capture and storage (CCS) applications with heat recovery. The agreement supports the companies’ joint target to reduce the cost of removing CO₂ emissions from industrial plants around the world.

Year

2020Technology collaboration for advanced heat integration

Just Catch FPSO – second generation

The first generation of the Just Catch offshore was developed on the studies for application on the Norwegian Continental Shelf. The second generation has been developed working with large scale FPSO leasing operators significantly decreasing both weight and footprint. Several studies and further developments are ongoing, reviewing the technical feasibility and costs of post combustion CO₂ capture and injection on various FPSO cases.

Year

2019 – 2021Target market: Lease operators of FPSO, major oil and gas companies

Full-scale carbon capture at Mongstad (TCM)

Design and EPC delivery of large-scale carbon capture plant at TCM. This full-scale CO₂ capture plant captures CO₂ from the gas fired combined heat and power plant at the Mongstad refinery. It is the world’s largest and most flexible plant for testing and improving carbon capture technologies. Aker Carbon Capture has not only tested its technology at the TCM facility, but has also designed and delivered the actual plant which has been in continuous operation since its opening in 2012. TCM is being used by companies and scientific communities from all over the world to develop and improve carbon capture solutions.

Year

2012Customer

Statoil

Porte Tolle CCU project

Front end engineering and design (FFED) for a CO₂ capture and compression plant for ENEL’s coal power plant in Porto Tolle, Italy.

Year

2010CO₂ capture capacity

1.000.000 TPA

Credit: Enel Spa

UK CCS demonstration project

Front end engineering and design (FFED) for a CO₂ capture and compression plant for Scottish Power’s coal fired power plant in Longannet, Scotland.

Winner of UK competition no.1.

Year

2010CO₂ capture capacity

2.000.000 TPA

Credit: ScottishPower